Introduction

Workplace security is more than something to tick off in compliance books: it’s also the foundation of efficient work and a healthy work environment. But accidents still happen every day, across all industries: as a result people are injured and both production and financial losses suffer. From slips and falls to faulty machinery, the causes of workplace accidents can be due to oversights at a single point or vulnerability over a wide range of procedures.

The good news? With smart safety solutions for today’s industries, real-time safety monitoring, and custom safety apps, many of these dangers can easily be reduced—or even eliminated—before anyone is hurt.

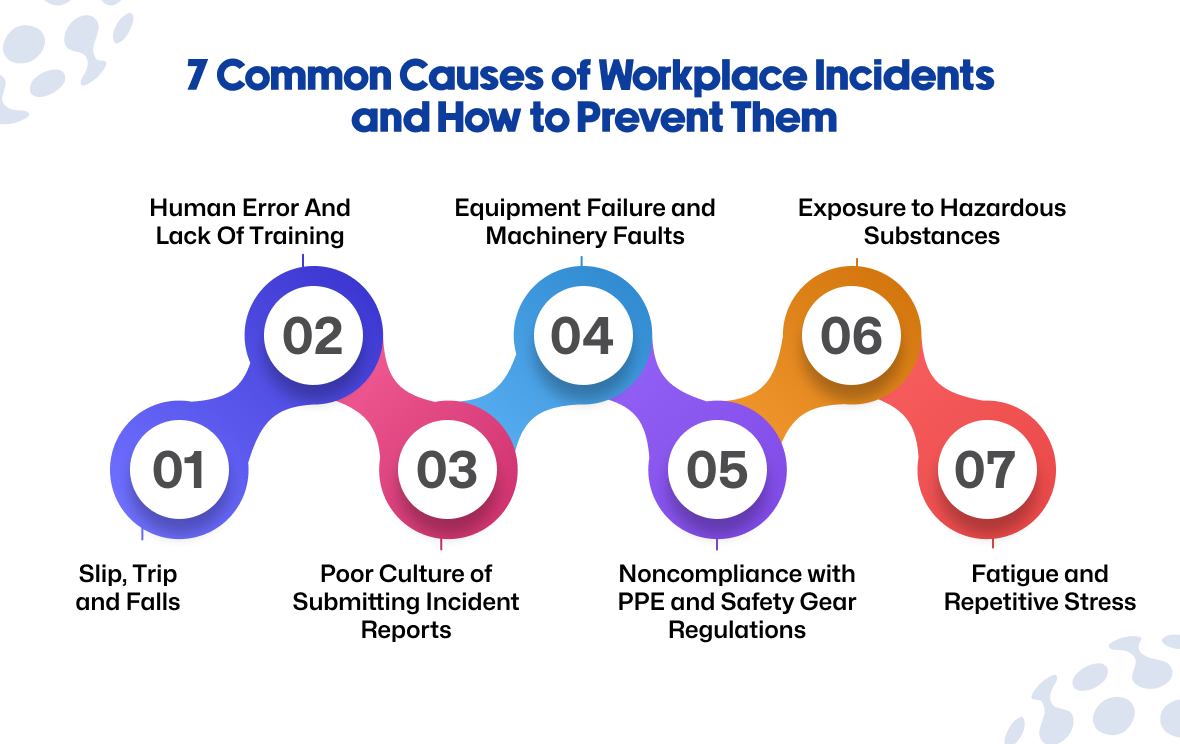

7 Common Causes of Workplace Incidents and How to Prevent Them

1. Slip, Trip and Falls

Undefeated still are uneven floors, wet surfaces, and inadequately lighted pathways–by any measure among the main causes of workplace accidents.

Prevention: Regular inspections and clear signage, plus AI-driven hazard detection systems to alert even checked out supervisors before it gets dangerous for employees. With real-time safety monitoring you can identify danger- fast, therefore can directly head off this (state).

2. Human Error and Lack of Training

Even the very best equipment can’t fully protect your plant against employees who are not trained or who are careless.

Prevention: Integrate hands-on instruction together with safety automation solutions that don’t rely on human judgment alone. (This means using systems like robot learning modules which can be specifically set up so all employees understand and follow safety procedures, then inform you if anything suspect happens.)

3. Poor Culture of Submitting Incident Reports

If people are scared to blame or feel it’s not worth reporting near-misses, a lot of useful safety information goes down the drain.

Prevention: Use automated monitoring systems and electronic collection of industrial safety data, combined with custom safety apps for industry, which will track patterns by region or time of day. This inculcates a culture where people are expected to report immediately, without potential penalty.

4. Equipment Failure and Machinery Faults

Outdated or poorly maintained equipment can lead to hazardous workplace injuries.

Prevention: Smart safety solutions help integrate predictive maintenance alarms. With sensors, the performance of the machinery can be monitored in real time, flagging potential problems before they turn into hazards.

5. Noncompliance with PPE and Safety Gear Regulations

Even when employees are provided with Personal Protective Equipment (PPE), not all wear it properly or at all.

Prevention: Through real-time safety monitoring systems, organizations can implement compliance tracking. If PPE is not used properly, smart wearables will alert the supervisor.

6. Exposure to Hazardous Substances

Chemicals, dust, and fumes—these are dangerous things to be around.

Prevention: Automated inventory tracking and alerts powered by AI can reduce overexposure. Just as a schedule that safety automation solutions provide for all necessary inspections guarantees strict compliance every time.

7. Fatigue and Repetitive Stress

Long shifts, insufficient rest breaks, and monotonous tasks—all these factors can lead to loss of attention and higher accident risks.

Prevention: Workforce management applications can balance loads, judge fatigue levels, and see that shift rotations are both safe and impartial.

Prevention with Smart Safety Solutions: Technology Boosts Safety into a Tech-Driven Realm

Today’s safety solutions go beyond checklists and warning signs. From real-time safety monitoring systems that instantaneously signal the presence of hazards to incident reporting apps fostering communication efficiency, technology is making safety more responsive, smarter, and reliable. With tailor-made software for workplace safety, companies can customize their prevention approaches in a way that suits their unique operations.

Data and Analytics’ Role in Incident Prevention

Data is not just a toolkit for business growth; it is a game-changer in safety risk management, too.

Through making all the data readily available from incident reports, IoT sensors, and compliance logs public, companies are now able to predict where points of high risk lie and address them before accidents happen. With safety automation solutions to take this all through you seamlessly, it’s possible today for you to make educated decisions that are clearly ahead of the curve.

How Aqlix IT Solutions Goes About Building You A Safer Workplace

Whether it’s industrial safety solutions, customized workplace software for safety, or a combination of the two, Aqlix IT Solutions has the right choice for people to make workplaces more secure and efficient.

At Aqlix IT Solutions, we provide industrial safety solutions, workplace software for safety, and smart safety solutions to help organizations build safer, more efficient environments.

The following questions and answers may help to shed some light on what we do.

- Custom Safety Platforms: Made for your industry’s needs

- IoT-Enabled Real-Time Monitoring: Instant alerts to hazards

- AI-Powered Analytics: Predict and prevent incidents before they occur

- Automation Solutions: From compliance tracking to preventive maintenance

Instead of reducing accident rates, improving compliance, or obtaining safety automation solutions on its own, our team makes sure your working environment is both compliant and ready for the future.

Conclusion

At Aqlix IT Solutions, we believe that workplace safety is not an expense but rather an investment in productivity, trust and employee welfare. The use of technology-driven solutions to address these seven common causes of workplace safety incidents will greatly reduce risks and cultivate a spirit of prevention.

When Aqlix IT Solutions is your technology partner, safety becomes more than a policy—it becomes your competitive advantage.

FAQ

Q1: What’s the most common reason for workplace accidents?

A: Falls, trips, slips, and similar hazards are always among the top causes, but they can be cut dramatically with preventive safety measures and warning systems.

Q2: How Can Technology Help Improve Work Safety?

Through real-time safety monitoring, AI analysis tools, Internet of Things sensors, or incident reporting apps, it is technology that can give us early warning of hazards and let a response be given more efficiently.

Q3: Can Aqlix provide custom workplace safety software for my company?

Yes Of course. Aqlix is a dealership specializing in software for workplace safety and customizes every item to suit your exact operational requirements.

Q4: Can safety automation solutions also work out for small businesses?

Absolutely—these systems are designed to scale and are suitable for businesses of any size, making safety both affordable and more efficient.

Q5: How do incident reporting apps encourage reporting?

If you want to improve the safety culture at work with smart safety solutions like accident reporting apps and customized workplace security software, they help achieve just that. On-site jobs in construction—we need your help. Contact Us Today can help make your workplace safer, smarter, and more efficient all at a stroke!