When safety is non-negotiable, your systems shouldn’t be generic.

From equipment hazards and regulatory mandates to workforce accountability, modern manufacturing facilities are facing continuous pressure to digitize their safety workflows. While off-the-shelf solutions exist, they often fail to meet specific protocols and real-time reporting needs. Also, they fall short on aligning with multi-role hierarchies.

All these reasons encourage companies to integrate custom-built Safety Management Systems (SMS) into their existing systems to meet their business requirements. As these strategic systems require a proactive approach, the one emerging technology that comes to mind is Oracle APEX.

But what does it actually cost to build an SMS using Oracle APEX?

Let’s break it down.

Understanding The Role Of Safety Management System In The Manufacturing Industry

A Safety Management System (SMS) provides a centralized, digital infrastructure. It is designed specifically to proactively monitor, manage, and enhance workplace safety. An effective SMS goes beyond reactive protocols, enabling manufacturers to standardize safety practices, reduce risk exposure, and create a data-driven safety culture across the organization.

Key Functions of a Safety Management System in Manufacturing:

- Real-Time Incident Reporting – This feature allows employees to report incidents in real time with time stamped entries. Moreover, they can geo-tag and upload media for more clarification. Immediate reporting allows for timely response at the incident areas.

- Root Cause Analysis – This feature helps identify underlying issues and prevent recurrence of the issues.

- Risk Assessments & Preventive Action Tracking – This feature helps evaluate operational risks systematically, assign mitigation tasks for proper action, and track implementation of CAPA (Corrective and preventative actions.)

- Digital Audit Trails & Checklists – It allows organizations to automate safety inspections, impose compliance checklists, and maintain secure audit trails for regulatory reviews and internal governance.

- Role-Based Dashboards – These easy to use dashboards offer smooth access to everyone, including stakeholders, shop floor supervisors, and compliance officers. This ensures accountability and focused action in the time of urgency.

- Seamless Integration with Core Systems – Smooth integration with ERP, Iot, and HRMS frameworks helps synchronize safety data with operations, workforce management, and equipment status at a centralized place.

In short, a well designed safety management system should provide a safe ecosystem that helps employees to automate accountability, offers actionable intelligence to implement safety measures, and must be equipped to engage with safety protocols in real time.

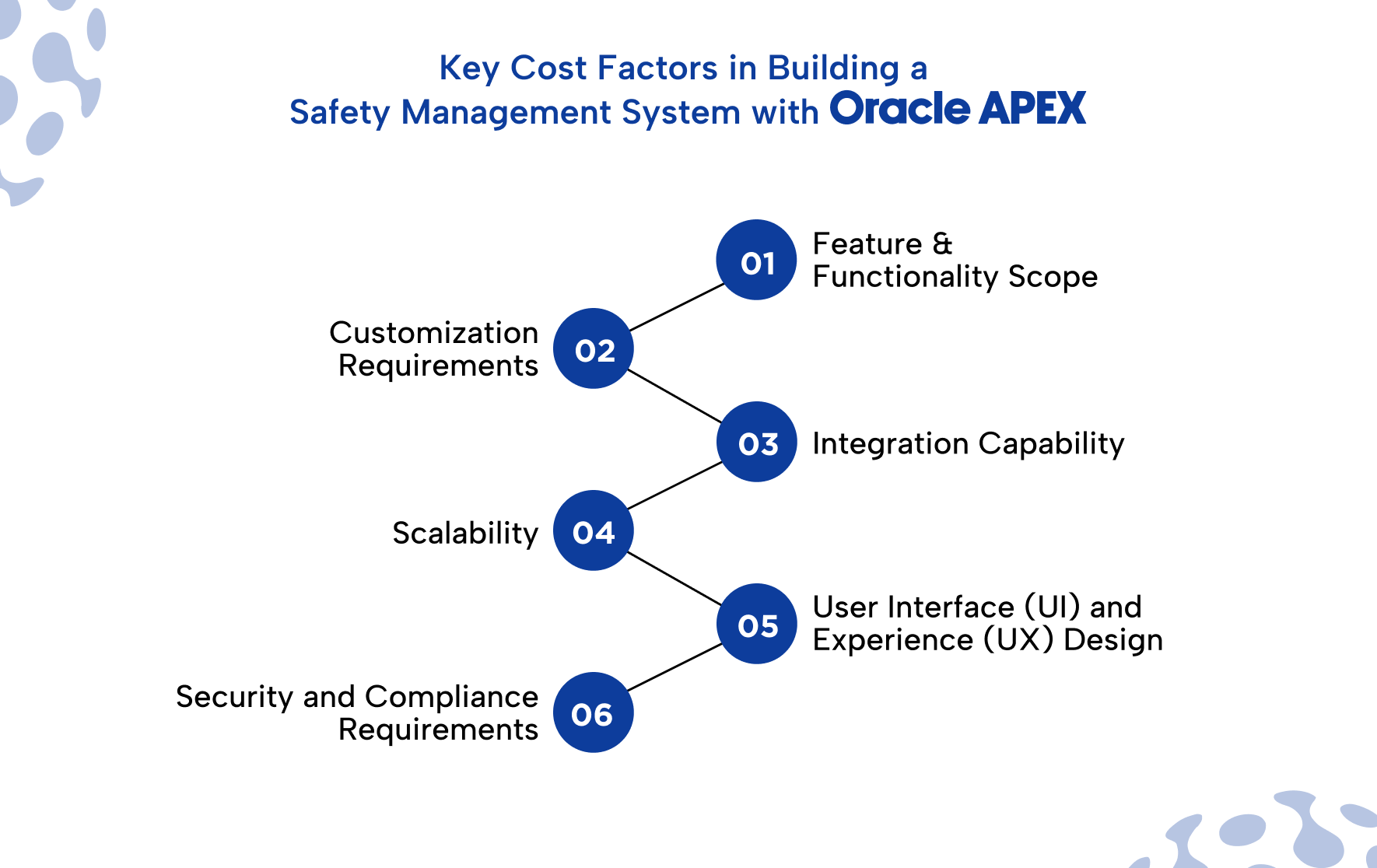

Key Cost Factors in Building a Safety Management System with Oracle APEX

The cost of developing a custom Safety Management System (SMS) with Oracle APEX depends on a combination of technical, operational, and strategic considerations. Let’s take a look at the important key factors that contribute directly to your budget, development timeline, and long-term value.

1. Feature & Functionality Scope

The core capabilities you want to add for your safety management software can significantly impact the development time and cost. A basic safety management system may include incident reporting and alert features, however, a custom designed solution can offer you as many features as you want. Here is a list of some features that you can get in the customized safety management system

- Automated alerts and notifications for incidents

- Real-time incident tracking

- Root cause analysis and CAPA workflows

- Role-specific dashboards

- Safety audits and inspections

- System compatibility with multiple devices

The more advanced functionalities you add to your system, the more its cost will be. .

2. Customization Requirements

The more you want to customize the proprietary workflows to align with your system, the more its development cost will increase.

Customizations may include:

- Tailored data models

- Custom approval hierarchies

- Personalized notification engines

- Workflow automation logic

All of these customizations require careful planning and architecture, substantially increasing the build time and cost of the project.

3. Integration Capability

Integrating your safety management system with other enterprise systems requires additional resources, which affects the overall cost.

Common integration points include:

- HRMS platforms

- ERP systems

- Document Management Systems (DMS)

- IoT devices and environmental sensors

Each integration requires design, testing, error-handling, and ongoing validation. The depth and number of integrations are key cost accelerators.

4. Scalability

If your organization operates across multiple plants or geographies, your SMS must scale accordingly. It might need these additional features:

- Multi location and language support

- Centralized vs. federated control models

- Role-based access and data partitioning

Oracle APEX offers unbounded scalability. However, to scale your system to that level you must consider thoughtful architecture and planning, impacting the overall cost of your project.

5. User Interface (UI) and Experience (UX) Design

Oracle APEX provides responsive design templates, however, many organizations choose to invest in an advanced interface to enhance usability and adoption.

Advanced UI/UX considerations include:

- Accessibility and usability testing

- Mobile-optimized experiences for field workers

- Custom themes aligned with your brand

- Interactive dashboards and visualizations

Incorporating interactive dashboards to the safety management system may require front-end expertise. Hiring additional resources for the project can increase the project cost.

6. Security and Compliance Requirements

Compliance is non-negotiable for industries with high regulatory scrutiny. Oracle APEX supports enterprise-grade security, but certain features may need additional efforts and hours to meet industry-specific mandates.

Common requirements:

- Role-based and field-level access controls

- End-to-end data encryption

- Immutable audit trails

- Logging and anomaly detection

- Digital signature support

Enhanced security features ensure data integrity but may increase setup and validation costs.

Key Features to Include in a Manufacturing Safety Management System (SMS)

In the manufacturing sector where complex machinery, high-risk operations, and hazardous materials are part of daily workflows, a robust Safety Management System (SMS) can prevent a large-scale disaster. So, here are some of the key features that define an effective SMS for manufacturing operations:

1. Comprehensive Risk Assessment and Hazard Identification

A robust SMS must offer comprehensive risk assessments and hazard identification, adapting to changing operational conditions. It allows real-time prioritization of risks based on evolving manufacturing processes, workforce behavior, and environmental factors, ensuring that the most pressing hazards are addressed promptly.

2. Real-Time Incident Reporting and Root Cause Analysis

Real-time reporting tools, often mobile-enabled, allow reporting of incidents in real-time and automate Root Cause Analysis (RCA). Immediate documentation of incidents reduces response time and leads to faster actions for resolutions, minimizing the risk of recurrence and improving workplace safety.

3. Documented Safety Policies, SOPs, and Compliance Protocols

Centralized documentation ensures easy access to updated Standard Operating Procedures (SOPs) and Safety Data Sheets (SDS). This centralization architecture streamlines safety protocol enforcement, ensuring uniform adherence across shifts and departments, while also maintaining audit-ready documentation for regulatory compliance.

4. Regulatory Compliance and Audit Management

A compliant SMS ensures adherence to international and local safety standards, such as ISO 45001 and OSHA regulations. Setting automated compliance tracking and audit management reduces the risk of non-compliance. It enables companies to meet regulatory requirements while minimizing penalties.

5. Emergency Preparedness and Response Framework

Structured and easy access to preparedness protocols, including Emergency Response Plans (ERPs) and mass notification systems is a must. It ensures that in the event of an emergency, all personnel are informed and can respond swiftly, minimizing injuries, property damage, and operational downtime.

6. Permit-to-Work (PTW) and Isolation Management

This feature ensures that high-risk tasks are authorized, controlled, and logged. By enforcing a controlled environment for hazardous operations, organizations can ensure that only qualified personnel access dangerous zones, reducing the likelihood of accidents due to human error.

7. Machine Safety and Predictive Maintenance Integration

The ability to integrate with Computerized Maintenance Management Systems (CMMS) enables proactive machinery health monitoring. Through maintenance scheduling, equipment failure prediction, and unexpected downtime reduction, this integration improves machine reliability, which in turn increases safety by lowering the likelihood of mechanical breakdowns that could cause accidents.

8. Behavior-Based Safety (BBS) Programs

The SMS should include Behavior-Based Safety (BBS) initiatives, emphasizing employees’ safety behaviors and attitudes. In order to lower risk on the ground, the system promotes a culture of safety by encouraging employees to report harmful activities, participate in safe behaviors, and take proactive measures to ensure their safety.

9. Integration with Enterprise Systems (ERP/EHS/HRMS)

Seamless integration with Enterprise Resource Planning (ERP), Environmental Health and Safety (EHS), and Human Resource Management Systems (HRMS) enhances operational visibility. This integration provides a unified view of safety, operational performance, and workforce training, aligning business goals with safety priorities across all departments.

10. Data Analytics and Predictive Insights

An advanced SMS leverages data analytics and predictive modeling to provide insights into safety trends and incidents. By analyzing safety data, predictive insights can highlight potential risks and allow for preemptive action, enabling businesses to focus on proactive rather than reactive safety management.

Final Thoughts

When it comes to developing a custom Safety Management System, it’s not about the cost. Our foremost priorities are software’s fit, flexibility, and future-readiness. And if you use the right approach, your simple compliance tool can be a competitive advantage in operational safety, efficiency, and governance.

If your plant deserves a safety system built around your protocols—not someone else’s template—Oracle APEX offers the foundation you need.